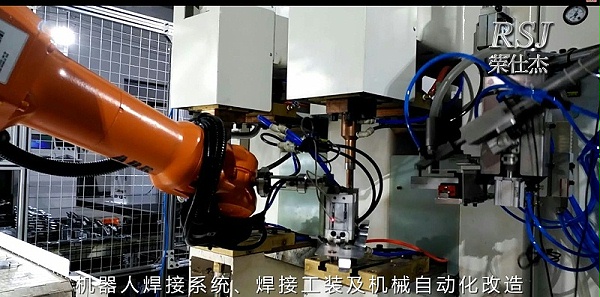

荣仕杰为您提供焊接机器人的相关信息:

应用案例请点击www.rongshijie.com首页观看视频!

焊接机器人是从事焊接(包括切割与喷涂)的工业机器人。根据国际标准化组织(ISO)工业机器人属于非标定制焊接机器人的定义,工业机器人是一种多用途的、可重复编程的自动控制操作机,具有三个或更多可编程的轴,用于工业自动化领域。为了适应不同的用途,机器人最后一个轴的机械接口,通常是一个连接法兰,可接装不同工具或称末端执行器。焊接机器人就是在工业机器人的末轴法兰装接焊钳或焊(割)枪的,使之能进行焊接,切割或热喷涂。

机型特点:

用于钣金、五金、铝合金精密焊接。应用于汽车、航天、船舶、动力电池、五金厨具、家电等行业。

Welding robots are industrial robots that are engaged in welding, including cutting and painting. According to the International Organization for Standardization (ISO) industrial robots, which are defined as non-standard custom welding robots, the industrial

robot is a versatile, reprogrammable automatic control manipulator with three or more programmable axes for industrial use. The field of automation. In order to adapt to different purposes, the mechanical interface of the last axis of the robot, usually

a connecting flange, can be fitted with different tools or end effectors. The welding robot is to attach a welding tong or a welding (cutting) gun to the end shaft flange of an industrial robot, so that it can be welded, cut or thermally sprayed.

Model features:

1. It is suitable for large-area space welding, intelligent operation of robots, flexible and reliable, can be linked by six axes, and can be welded in any space, not limited to plane welding.

2. Customers can customize fixtures according

to production needs.

3. It can realize double-station or multi-station welding operation, saving time for product installation fixtures and greatly improving production efficiency.

4. With the domestic first wobble welding head, its unique

wedge-shaped vibration method makes the weld be widened, which makes laser welding more widely used. For larger workpieces and wider welds, laser high-efficiency precision welding can be realized. And the welding quality effect is obviously better

than the ordinary welding head. The surface of the weld is relatively flat and beautiful, and the welding quality is good.

5, high repeatability, can be repeated many times without errors, no consumables, flexible processing, low operating costs.

6, some places can replace manual operation, suitable for some difficult space welding.

Application range:

Used for precision welding of sheet metal, hardware and aluminum alloy. Used in automotive, aerospace, marine, power batteries,

hardware kitchen utensils, home appliances and other industries.