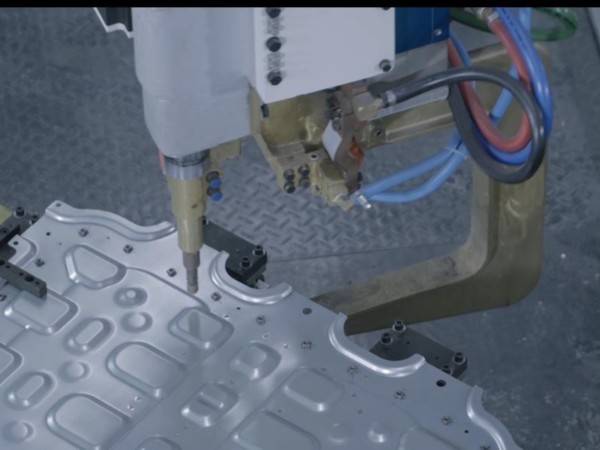

荣仕杰为您详细解释点焊机器人在机械制造中的应用实例!详细视屏案例请点击上方首页观看

点焊对所用的机器人的要求是不很高的。因为点焊只需点位控制,至于焊钳在点与点之间的移动轨迹没有严格要求。这也是机器人最早只能用于点焊的原因。点焊用机器人不仅要有足够的负载能力,而且在点与点之间移位时速度要快捷,动作要平稳,定位要准确,以减少移位的时间,提机械臂。

高工作效率。点焊机器人需要有多大的负载能力,取决于所用的焊钳形式。对于用与变压器分离的焊钳,30~45kg负载的机器人就足够了。但是,这种焊钳一方面由于二次电缆线长,电能损耗大,也不利于机器人将焊钳伸入工件内部焊接;另一方面电缆线随机器人运动而不停摆动,电缆的损坏较快。因此,目前逐渐增多采用一体式焊钳。这种焊钳连同变压器质量在70kg左右。考虑到机器人要有足够的负载能力,能以较大的加速度将焊钳送到空间位置进行焊接,一般都选用100~150kg负载的重型机器人。为了适应连续点焊时焊钳短距离快速移位的要求。新的重型机器人增加了可在0.3s内完成50mm位移的功能。这对电机的性能,微机的运算速度和算法都提出更高的要求。

英文版:

The requirements for spot welding on the robot used are not very high. Because spot welding requires only point control, there is no strict requirement for the movement path of the welding tongs between points. This is also the reason why robots can only

be used for spot welding. The spot welding robot not only needs to have sufficient load capacity, but also has a fast speed when moving between points, and the movement should be smooth and the positioning should be accurate to reduce the displacement

time and lift the robot arm.

High work efficiency. How much load capacity a spot welding robot needs depends on the type of welding tongs used. For welding tongs separated from the transformer, a robot with a load of 30 to 45 kg is sufficient.

However, on the one hand, the welding tongs have large electrical energy loss due to the length of the secondary cable, and are not conducive to the robot to extend the welding tongs into the workpiece. On the other hand, the cable runs without the robot

moving, and the cable is damaged quickly. . Therefore, the use of integrated welding tongs is gradually increasing. This welding tongs together with the transformer quality is around 70kg. Considering that the robot has sufficient load capacity, the welding

tongs can be sent to a space position for welding with a large acceleration, and a heavy-duty robot with a load of 100 to 150 kg is generally selected. In order to meet the requirements of short-distance rapid displacement of welding tongs during continuous

spot welding. The new heavy-duty robot adds the ability to perform 50mm displacement in 0.3s. This puts higher requirements on the performance of the motor, the operation speed of the microcomputer and the algorithm.

咨询热线

400-693-3363